For prescription Sunglasses and Eyewear, the best choice is Bigatmo.

Bigatmo prescription sunglasses are the right choice for pilots, for sports and for driving. This is due to the combination of active technologies and attention to detail, meaning they perform exceptionally well in many different environments.

Just some of the aspects we’ve brought together, in order to achieve outstanding performance:

- Bigatmo sun-lens research, development and environmental testing

- The most advanced lens material currently available

- Sophisticated and versatile digital prescription lens designs

- High definition digital freeform lens generation

- Specialist glazing in our cutting-edge finishing lab

The importance of having the technology in the first 0.9mm of the lens

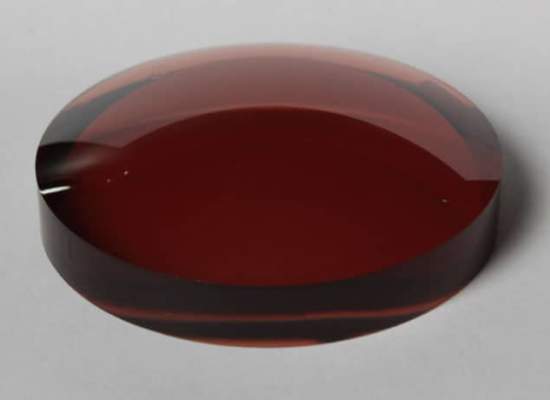

Every pair of Bigatmo RX prescription sunglasses starts with a pair of semi-finished lens-blanks.

The front surface of the lens-blank is the finished part, and it carries all the sunlens filter technology in the first 0.9 mm, which is pretty amazing.

Your prescription is then generated and polished onto the back surface of the lens. This ensures that your prescription lenses have the same sun-filters as the plano (non-prescription lenses) we offer.

These are:

- Alutra- (our copper/brown photochromic lens)

- Zeolite – (our grey high contrast lens) and

- Zeolite Polarized- (our grey high contrast lens with an added polarized filter).

We also offer clear and Transitions prescription lenses: RX Prescription Lens Choices

What makes the optical properties of NXT®/Trivex® exceptional?

Our lenses are cast from NXT®/Trivex® in glass moulds and cure very slowly in a temperature-controlled environment. This results in very low internal stresses and excellent optical properties.

Every lens material deforms slightly during the manufacturing process due to the pressure of the cutting tools on the lens surface. However NXT®/Trivex® has excellent mechanical properties with practically no deformation and this contributes to a more accurate prescription lens. This is just one of the reasons NXT®/Trivex® is seen by the optical industry as such an excellent choice.

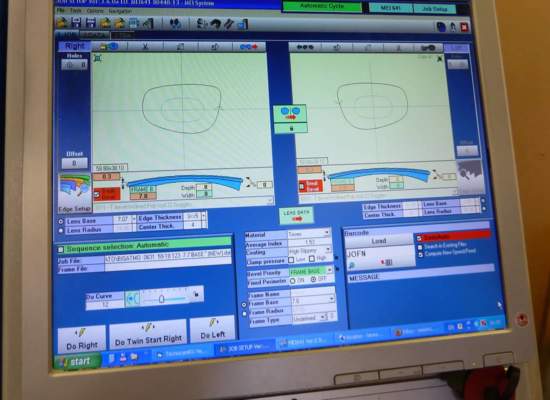

How your prescription is placed onto the lens

Applying a prescription to a lens is a complex multi-stage process. It takes place at our “finishing” labs. We use the latest HD Digital Freeform technology. This is when your prescription is “generated” and polished onto the back of the lenses. We apply coatings, cut, and edge the lens, and finally fit it into your choice of frame.

How RX lens design and manufacture improved recently

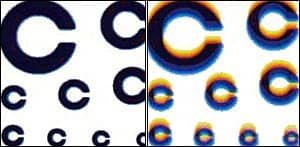

Over recent years incredible advances have been made in the design and manufacture of prescription lenses. Until quite recently applying a prescription to a wrapped, curved lens was a tricky process. Very few labs tried, and even fewer attained acceptable results.

Digital lens generating and polishing technology changed all that. Now allowing different kinds of prescription to be placed on the back of the lens, using computer-controlled machinery.

A little while ago the best machinery would generate prescriptions using about 5,000 co-ordinates – now our lenses are prepared using in excess of 40,000.

We produce all Bigatmo RX prescription sunglasses – both single vision and progressive – using the latest generation HD Digital Freeform systems.

Varifocal lenses

In broad terms, the surface of a varifocal (or progressive) lens is divided into three areas.

The top part is for viewing distant objects, the bottom part is for reading and close work. The part in-between handles the focal lengths between reading and distance – an instrument panel for example.

When driving or flying, the intermediate area is particularly important. A lens which is natural to use is a real advantage. The idea is that the areas blend into each other, thereby replicating natural vision.

What about lens design and why does it matter to me?

Excellent lens design is essential, in order to take advantage of HD Digital Freeform systems and NXT®/Trivex® technology. You won’t be totally surprised to hear that there are companies that specialise in producing digital lens designs. Now there are designs to suit individual lifestyles.

We provide varifocals which are particularly versatile and feel as natural as possible. This makes them an excellent choice across a broad range of activities.

In conjunction with our labs, we’ve considered very many lens designs and trialled a good number too. We choose, what we consider, the best and most versatile currently available. We always keep our finger on the pulse.

Lens design continues to evolve and so we regularly review the new, to make sure that we offer the best.

All the lens designs that we use are quite easy to adapt to, and our customers often tell us how natural they feel to use.

We have very high success rates with these designs. It’s worth remembering though, that if you haven’t used varifocals before, you may have a settling in period. You may need to persevere for a while, until you get used to them. Think of this as your brain reading and understanding the new way data is presented by your eyes. Your brain is learning to use a new tool. But the effort you put in will be rewarded when things settle and you gain the full benefit of your glasses.

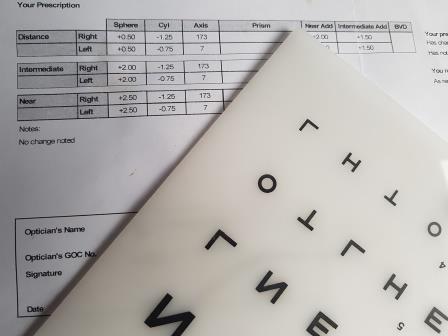

Eye tests, fittings and measurements for prescription sunglasses

It’s crucial to supply precise information. Then you benefit from all this amazing technology.

Visit a good optometrist for a fresh eye test. It’s important, as the more precise and up to date your eye test is, the better and longer-lasting the lenses will be.

We also produce bespoke solutions. Varifocal sunglasses for glider pilots, for example, are quite different from the norm. Glider pilots need a larger area for distance vision and smaller areas for intermediate and near vision. This lens design has become our standard and a popular choice amongst the gliding community.

Like our glider pilot, if you want something different, special, or that you just can’t find in high street stores, please contact us. We love to chat about your needs and how we might be able to help.

If your interested in a pair for yourself, pleases contact us for a quick quote:

- Call us : +447553565140 or Email:[email protected]